6S Cleaning Checklist Template

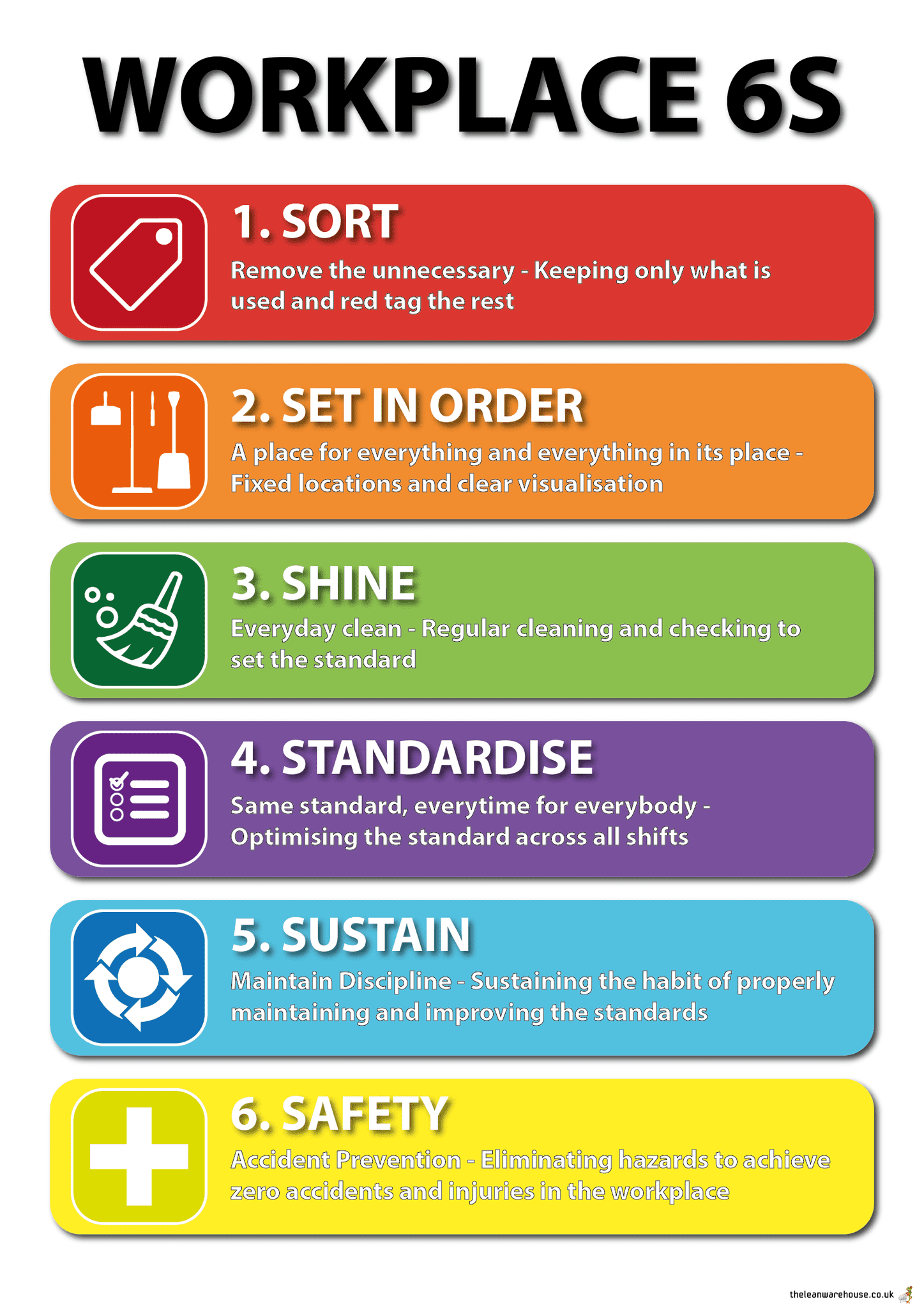

6S Cleaning Checklist Template - The goal of 6s is to ensure that safety is a part. The 6s method is a system that aims to promote and sustain high levels of productivity and safety throughout an organization. The six steps of the 6s method are: ⭐discover the meaning, process, and standards of 6s, including its focus on safety and workplace organization. Sort, systematize, clean, standardize, self. 6s is often thought of as the foundation for continuous improvement. Learn what 6s lean means in the workplace, how to incorporate safety into your existing 5s system, and develop a highly productive and safe workspace. It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine (aka. 6s lean manufacturing combines the five key tenants of 5s — sort, straighten, shine, standardize, and sustain — with safety. This system builds on the 5s method,. The goal of 6s is to ensure that safety is a part. Electronics · contact us · knowledge base · download 6s, a modification of the 5s methodology which includes safety as the 6th s. It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine (aka. It is a comprehensive approach that helps create a clean,. ☑️learn what 6s methodology is and its role in lean manufacturing. Sort, set in order, shine, safety, standardize, and sustain. By integrating safety as a core component, the 6s approach emphasizes the importance of. Sort, systematize, clean, standardize, self. This system builds on the 5s method,. The goal of 6s is to ensure that safety is a part. By integrating safety as a core component, the 6s approach emphasizes the importance of. ☑️learn what 6s methodology is and its role in lean manufacturing. ⭐discover the meaning, process, and standards of 6s, including its focus on safety and workplace organization. 6s, a modification of the 5s methodology. 6s lean manufacturing combines the five key tenants of 5s — sort, straighten, shine, standardize, and sustain — with safety. While traditionally considered only applicable to a manufacturing environment, it is highly relevant for. This system builds on the 5s method,. The 6s method is a system that aims to promote and sustain high levels of productivity and safety throughout. 6s, a modification of the 5s methodology which includes safety as the 6th s. The 6s method, also referred to as 5s + safety, assists in maintaining productivity and safety in the workplace. 6s is an expanded version of the 5s lean management methodology, commonly used in manufacturing and complex workplace environments to streamline operations. By integrating safety as a. ☑️learn what 6s methodology is and its role in lean manufacturing. 6s is an expanded version of the 5s lean management methodology, commonly used in manufacturing and complex workplace environments to streamline operations. The goal of 6s is to ensure that safety is a part. ⭐discover the meaning, process, and standards of 6s, including its focus on safety and workplace. While traditionally considered only applicable to a manufacturing environment, it is highly relevant for. This system builds on the 5s method,. 6s is often thought of as the foundation for continuous improvement. Sort, set in order, shine, safety, standardize, and sustain. It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine. ☑️learn what 6s methodology is and its role in lean manufacturing. It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine (aka. Sort, systematize, clean, standardize, self. The goal of 6s is to ensure that safety is a part. ⭐discover the meaning, process, and standards of 6s, including its focus on. Learn what 6s lean means in the workplace, how to incorporate safety into your existing 5s system, and develop a highly productive and safe workspace. The 6s method, also referred to as 5s + safety, assists in maintaining productivity and safety in the workplace. It is a comprehensive approach that helps create a clean,. Electronics · contact us · knowledge. It is a comprehensive approach that helps create a clean,. This system builds on the 5s method,. The goal of 6s is to ensure that safety is a part. Electronics · contact us · knowledge base · download It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine (aka. While traditionally considered only applicable to a manufacturing environment, it is highly relevant for. Sort, systematize, clean, standardize, self. By integrating safety as a core component, the 6s approach emphasizes the importance of. 6s, a modification of the 5s methodology which includes safety as the 6th s. ☑️learn what 6s methodology is and its role in lean manufacturing. Sort, systematize, clean, standardize, self. The 6s method is a system that aims to promote and sustain high levels of productivity and safety throughout an organization. It is a comprehensive approach that helps create a clean,. ⭐discover the meaning, process, and standards of 6s, including its focus on safety and workplace organization. Electronics · contact us · knowledge base ·. By integrating safety as a core component, the 6s approach emphasizes the importance of. ☑️learn what 6s methodology is and its role in lean manufacturing. Electronics · contact us · knowledge base · download Sort, set in order, shine, safety, standardize, and sustain. 6s lean manufacturing combines the five key tenants of 5s — sort, straighten, shine, standardize, and sustain — with safety. 6s is an expanded version of the 5s lean management methodology, commonly used in manufacturing and complex workplace environments to streamline operations. The goal of 6s is to ensure that safety is a part. The six steps of the 6s method are: It is a lean process improvement tool that stands for sort, set in order (aka straighten or stabilize), shine (aka. This system builds on the 5s method,. The 6s method is a system that aims to promote and sustain high levels of productivity and safety throughout an organization. 6s, a modification of the 5s methodology which includes safety as the 6th s. ⭐discover the meaning, process, and standards of 6s, including its focus on safety and workplace organization. Learn what 6s lean means in the workplace, how to incorporate safety into your existing 5s system, and develop a highly productive and safe workspace. 6s is often thought of as the foundation for continuous improvement.Implementing 6s at your work place Artofit

6s Lean

Safety Poster 6S Lean Workplace 6 Components Defined CS747562

6S process for company. Sort, shine, sustain, standardize, set in order

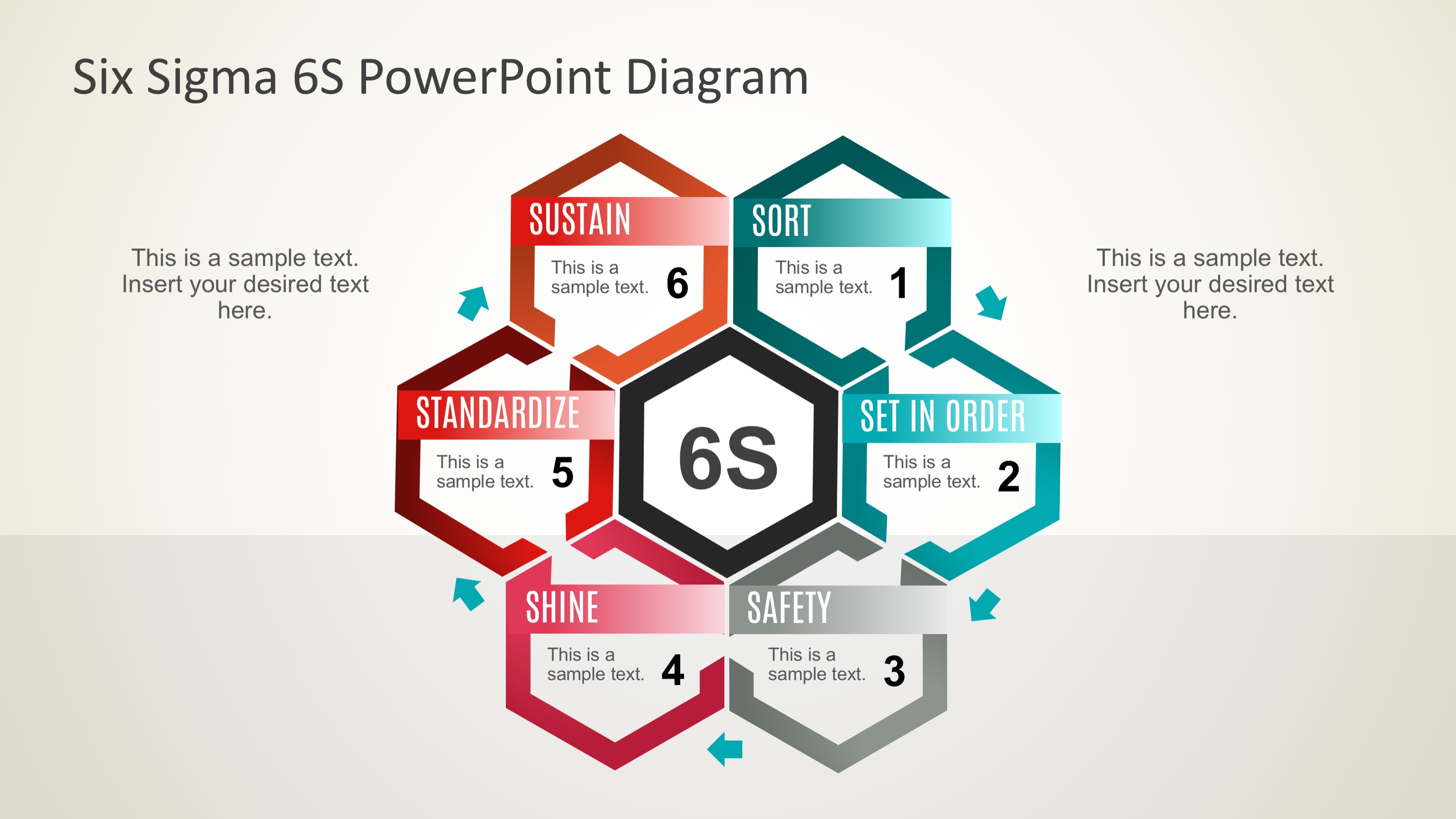

Six Sigma 6S PowerPoint Diagram SlideModel

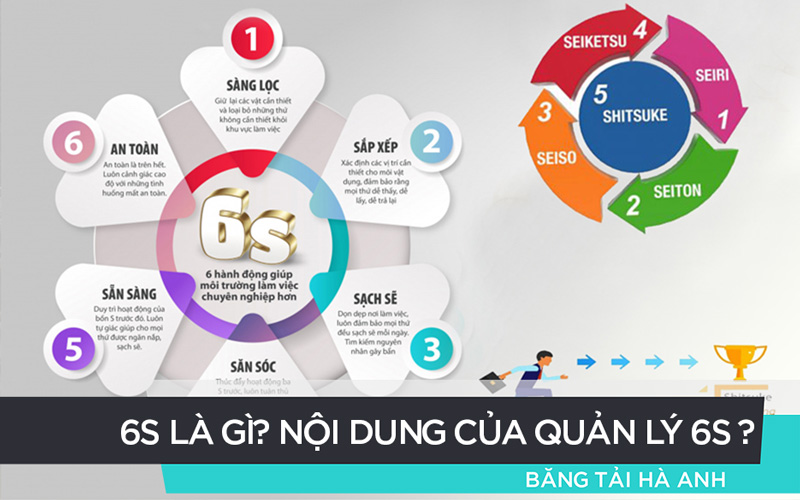

6s Là Gì? Nội Dung Của Hệ Thống Quản Lý 6s Như Thế Nào?

Implementing 6s at your work place Artofit

The 6S's of Warehouse Maintenance B.I.G. Logistics

6s For Safety Poster Create A Lean Workplace Creative Safety

6S 6S Template

While Traditionally Considered Only Applicable To A Manufacturing Environment, It Is Highly Relevant For.

The 6S Method, Also Referred To As 5S + Safety, Assists In Maintaining Productivity And Safety In The Workplace.

It Is A Comprehensive Approach That Helps Create A Clean,.

Sort, Systematize, Clean, Standardize, Self.

Related Post: